I was looking for a sturdy coffee table with simple, modern lines. Something with solid wood and a steel frame. I used to have a coffee table with a shelf underneath. That was extremely convenient to store all the stuff that would otherwise lay on the table itself so I wanted a table with a shelf. I went to the usual places, IKEA, CB2, Crate and Barrel, Room and Board, Pier 1, Ethan Allen and a few other local stores but sure enough I couldn’t find the right coffee table (at a reasonable price too). Since nobody ever built what I needed, I had an excuse to do what I wanted to do anyway, build my own coffee table.

There were two main issues. First, I can’t weld or do any metal work. Second, I’ve never been able to glue two boards side by side properly. For the metal work, I happen to know a great guy who can do this kind of thing, I just had to sketch what I needed.

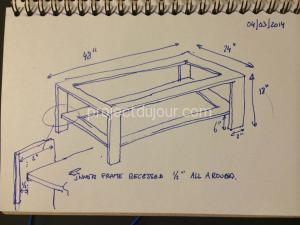

Sketches for the frame

I sent him a photo of my drawing and a week later it was ready. I had a few surprises when he delivered it. To start, this thing is heavy, very heavy. I thought the 1/2″ x 2″ profiles would be hollow but they are not. This is solid steel all around and I like it. The frame was also much nicer than I expected, to the point that I hesitated to hide it under two large wood slabs. I thought of using glass panels but I really wanted something warmer.

For the two surfaces, I chose solid maple. It’s fairly easy to find at the local hardware store and quite hard to the touch so it should resist TV dinners, mugs of hot coffee, beer bottles and kids dancing on the table. I had to glue a few boards together to make the 24″ width, namely four 1″ by 6″ boards and a 1″ by 4″ in the middle. I had to cut the 4″ wide board to make it narrower using a table saw and I finished the side with a portable wood planer. The boards are glued together with some biscuits to maintain the horizontal alignment and reinforce the tabletop.

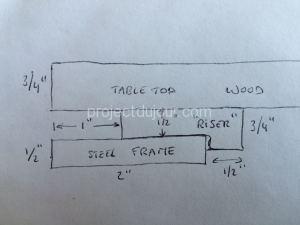

I was not very careful when I used my biscuit joiner and forgot to check the alignment before glueing . I ended up with some visible offsets between the boards and spent hours trying to sand the differences of level between the boards. I still can’t weld and still can’t glue two boards together. Once I had the two boards prepared, I placed them on top of the frame. The effect wasn’t very pleasant, the frame was almost totally hidden and the table looked too massive for my taste. I placed some 1″ by 2″ strips under the boards to make the table look lighter and I liked the effect.

To raise the tabletop, I glued and nailed a 2″ by 1″ strip of maple all around the tabletop with a 1″ recess. I then placed the tabletop and shelve on the frame to mark the inner shape of the frame with a pencil. Using a router, I removed a 1/4″ from the trim to match the frame’s openings. The boards are pretty heavy and fit so nicely inside the frame that I was almost tempted to skip on adding screws to hold the wood to the frame.

I then had some fun sanding and applying 3 coats of polyurethane clear finish.

I finally drilled 16 holes in the steel frame (8 for each wood plank) and screwed the tabletop and shelve to the frame using stainless steel screws.

If I may ask, about how much did it cost to have the steel frame made?

Looks awesome!

It’s been a while but I think it was around $400. https://www.facebook.com/Tim-Scofield-Studios-261993493855415/